Shinko and Insulation Maintenance

Shinko and Insulation Maintenance

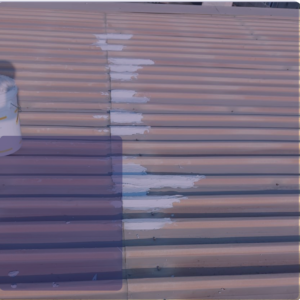

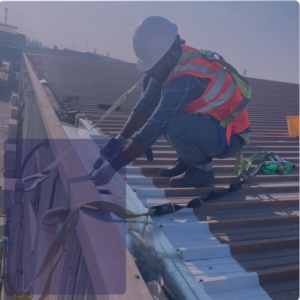

Shinko panels and insulation play a vital role in protecting buildings and structures from environmental factors such as heat, moisture, and rain. Altamayz Group for Maintenance and Operations provides comprehensive and specialized maintenance services for Shinko panels and insulation to ensure optimal performance, durability, and long-term thermal protection. We apply best technical practices using high-quality materials and modern techniques to maintain structural integrity and extend the service life.

Our Shinko and Insulation Maintenance Services:

1. Shinko Panel Repair and Maintenance

- Comprehensive inspection to detect any damage or cracks in the panels.

- Repairing gaps and fractures to ensure panel integrity and prevent deterioration.

- Replacing damaged sections with new panels to enhance appearance and functionality.

- Reinforcing panel stability and ensuring the safety of the supporting structure.

2. Water Leak Detection and Prevention

- Identifying leakage points using advanced techniques such as thermal imaging and moisture scanning.

- Sealing cracks and voids with weatherproof and water-resistant sealants.

- Insulating joints and panel connections to provide complete protection from water infiltration.

3. Repainting and Corrosion Protection

- Cleaning panels thoroughly to remove dirt and debris, ensuring optimal paint adhesion.

- Applying anti-rust and corrosion-resistant coatings to extend panel lifespan.

- Restoring colors to improve external aesthetics while maintaining insulation properties.

- Using reflective coatings to reduce heat absorption in high-temperature areas.

4. Thermal and Waterproofing Enhancement

- Installing additional thermal insulation layers to improve energy efficiency.

- Implementing comprehensive waterproofing systems using specialized membranes to prevent leaks.

- Sealing joints and welds with advanced insulating materials to maximize protection.

5. Structural Support and Fastener Repair

- Inspecting and reinforcing the metal frameworks supporting the panels.

- Repairing or replacing corroded or loose fasteners to ensure panel stability.

- Applying anti-rust treatments to metal structures to prevent future corrosion.

6. Preventive and Routine Maintenance

- Conducting preventive maintenance programs, including regular inspections and early diagnostics.

- Cleaning panels and insulation to remove corrosive agents such as dust and pollutants.

- Providing periodic reports outlining panel conditions and future maintenance recommendations.

Shinko and Insulation Maintenance

Shinko panels and insulation play a vital role in protecting buildings and structures from environmental factors such as heat, moisture, and rain. Altamayz Group for Maintenance and Operations provides comprehensive and specialized maintenance services for Shinko panels and insulation to ensure optimal performance, durability, and long-term thermal protection. We apply best technical practices using high-quality materials and modern techniques to maintain structural integrity and extend the service life.

Our Shinko and Insulation Maintenance Services:

1. Shinko Panel Repair and Maintenance

- Comprehensive inspection to detect any damage or cracks in the panels.

- Repairing gaps and fractures to ensure panel integrity and prevent deterioration.

- Replacing damaged sections with new panels to enhance appearance and functionality.

- Reinforcing panel stability and ensuring the safety of the supporting structure.

2. Water Leak Detection and Prevention

- Identifying leakage points using advanced techniques such as thermal imaging and moisture scanning.

- Sealing cracks and voids with weatherproof and water-resistant sealants.

- Insulating joints and panel connections to provide complete protection from water infiltration.

3. Repainting and Corrosion Protection

- Cleaning panels thoroughly to remove dirt and debris, ensuring optimal paint adhesion.

- Applying anti-rust and corrosion-resistant coatings to extend panel lifespan.

- Restoring colors to improve external aesthetics while maintaining insulation properties.

- Using reflective coatings to reduce heat absorption in high-temperature areas.

4. Thermal and Waterproofing Enhancement

- Installing additional thermal insulation layers to improve energy efficiency.

- Implementing comprehensive waterproofing systems using specialized membranes to prevent leaks.

- Sealing joints and welds with advanced insulating materials to maximize protection.

5. Structural Support and Fastener Repair

- Inspecting and reinforcing the metal frameworks supporting the panels.

- Repairing or replacing corroded or loose fasteners to ensure panel stability.

- Applying anti-rust treatments to metal structures to prevent future corrosion.

6. Preventive and Routine Maintenance

- Conducting preventive maintenance programs, including regular inspections and early diagnostics.

- Cleaning panels and insulation to remove corrosive agents such as dust and pollutants.

- Providing periodic reports outlining panel conditions and future maintenance recommendations.

Picture Of Our Works